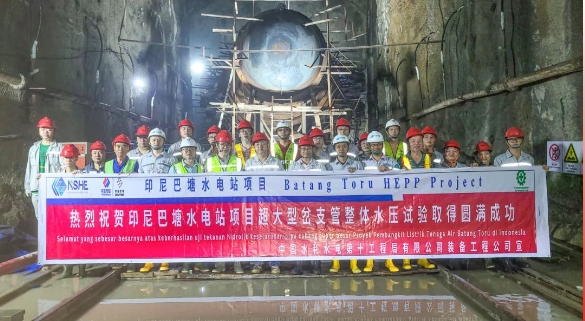

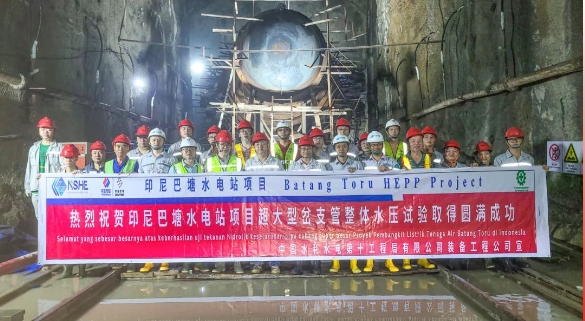

The water pressure test of the bifurcation branch pipe of Batang Hydropower Station was successful

Keywords: Batang Hydropower Station, Hydroelectric Power Generation, Electric Power Construction

At 1:30 am local time on June 17th, with the instruction to stop the pressure transmitted through the intercom, the overall water pressure test of the super large branch pipe of the Batang Hydropower Station in Indonesia, which was constructed by the Tenth Bureau of Hydroelectric Power, was successfully completed. This marks a significant achievement in the technical research of the project and lays a solid foundation for ensuring the project's timely power generation and operation.

The hydraulic test of the ultra large branch pipe in the tunnel of this project is a key node project of the project construction. The overall hydraulic test method is adopted, which includes one main branch, two auxiliary branches, a branch pipe connection section, and four branch pipes. The ultra large branch pipe is made of Q690SD high-strength steel material, with a common cutting ball diameter of 9.12 meters, a total weight of 8500 tons, and a water filling volume of 6750 cubic meters.

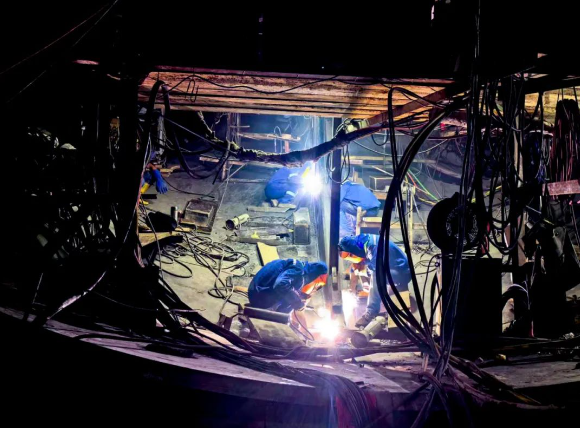

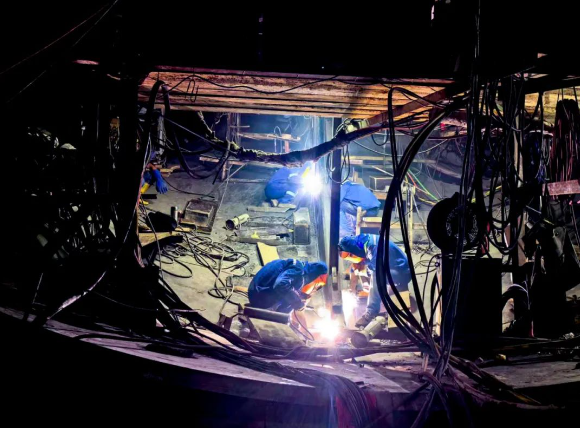

The project team began precise deployment and coordinated several months in advance, completing high standard preparatory work such as the layout of filling and drainage pipelines, the laying of stress and strain gauges, and the establishment of emergency support systems. After 10 days of uninterrupted pressure, they successfully achieved a water pressure of 3.7 megapascals and maintained it for 30 minutes.

After joint inspection, all data are better than the design requirements, fully reflecting the significant achievements of the project department in the application of "four new" technologies, the development of new quality productivity, as well as the CO2 welding process adopted in the manufacturing, installation and welding of branch pipes, and the welding application of submerged arc welding in rib plates and other positions. This provides favorable conditions for the subsequent installation and effective performance of the steel pipe main body of the project, and is of great significance for the improvement of the company's pressure steel pipe manufacturing and installation business skills and core competitiveness in the field of ultra large metal structures and special high-strength steel.

It is reported that Batang Toru Hydropower Station is located in Batang Toru Town, the middle and lower reaches of Batantoru River in the south of North Sumatra Province, Indonesia. It is an important project for the national development of the "the Belt and Road", and also the largest hydropower project under construction overseas by PowerChina.

The total installed capacity of the power station is 510 megawatts, with a total storage capacity of 2.58 billion cubic meters and a designed rated head of 275.86 meters. After the completion of the project, the annual power generation will reach 2070.53 gigawatt hours, which can greatly alleviate the power shortage problem on most of Sumatra Island and benefit millions of people.